Proofware Tools

-in-one inspection of all packaging elements

Packaging isn't just about text.

What about graphics, barcodes, spelling and Braille?

With apps to inspect different elements within your packaging,

Proofware is the 1st all-in-one inspection solution that has all your packaging covered.

Inspect Word files, PDFs, UPC codes, Data Matrix and more in seconds.

DocuProof

- Text Verification, Document Inspection and Comparison Solution

DocuProof is a text comparator for text heavy documents.

Well suited for the inspection of contracts, publications,

inserts, manuscripts, SOPs etc.

DocuProof text verification software compares text in virtually any language.

Even compare unlike files (graphic vs. Word files).

Quickly and easily find changes in fonts, sizes, deletions,

inserts, spelling, and location.

DocuProof dramatically eases the challenges that professionals face

on a daily basis when trying to manage and ensure the accuracy of

packaging components, contracts, publications, and manuscripts.

DocuProof can help you

- Compare PDF to text documents

- Streamline & expedite approvals

- Inspect PDF to Word files

- Ensure copy integrity

- Proofread PDF files

- Ensure accurate typesetting

- With multi-language document compare

- Reduce time-to-market

- Ensure accurate typesetting

Document types

- Inserts

- Website content

- Labels

- Legal docs

- Leaflet

- Manuscripts

- Booklets

- Journals

- Brochures

- Magazines

- Ads

- Publications

- SOP's

- Reports

DocuProof Features

- Text Document comparison:

- Detect all changes between�

MS Word, MS Excel, PDF, XML & text files,�

regardless of layout or format.

- Font size tolerance (As per new European Standards):

- Font size tolerance setting allowing for detection

of font size� differences as small as 0.01 .

- Inspect text in all Languages including Braille.

- Partial text inspection:

- Compare specific paragraphs and pages.

- Web page inspection:

- Ability to inspect *.mhtml� and *.mht files

versus MS Word� and PDF files.

- Support for templates:

- Ability to inspect QRD templates for �EMA submissions

and SPL templates for� FDA submissions.

- Find & compare feature:

- Ability to find multiple matches between

master & revision documents.

- Table inspection technology

- Ability to inspect tables cell-by-cell in seconds.

- Ability to save proofreading project before it’s

complete and resume work later.

- Available validation documentation and execution (IQ,OQ, PQ).

- Spell-checking capability:

- English medical dictionary (optional) and

brand owners’ dictionary.

�Includes a large list of supported languages.

- Annotation feature for file collaboration:

- View all differences & comments as PDF annotations.

- Connects to major artwork management systems (AWS).

- 21 CFR part 11 / Annex 11 compliant.

- Comprehensive reporting.

- Save Projects Functionality.

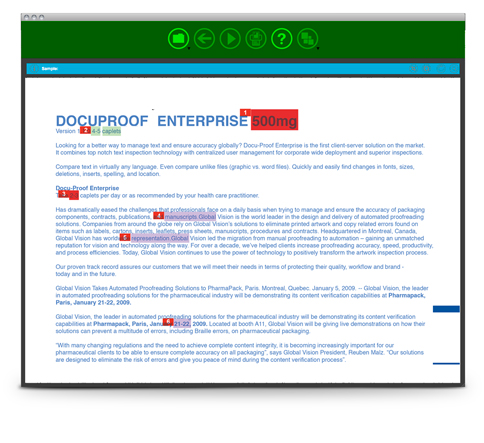

DocuProof Report

All differences are highlighted and color coded.

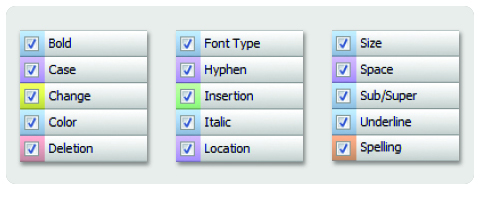

DocuProof Inspection Filters

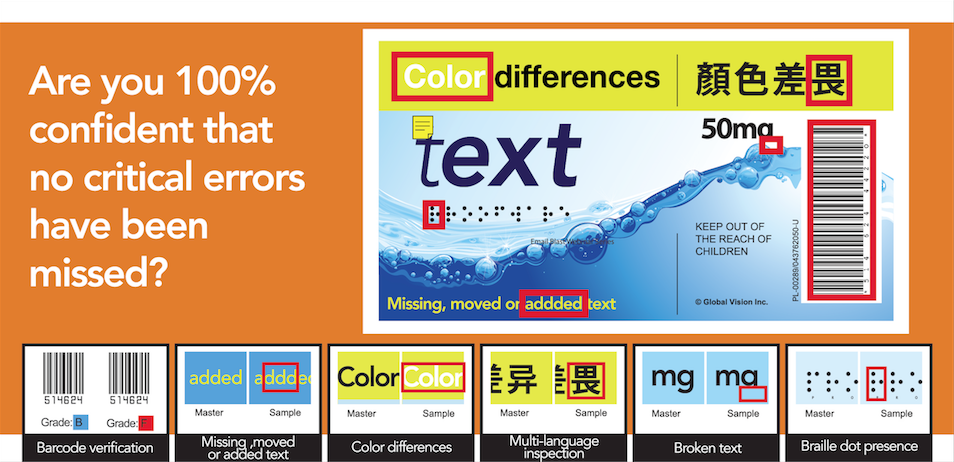

ArtProof - Artwork Inspection Solution

Inspect artwork with pixel-precision.

Reduce errors, rework, recalls and proofreading time.

Developed for the graphic design, pre-press and printing industry,

ArtProof inspects artwork with pixel precision, dramatically increasing

packaging accuracy while reducing inspection times.

ArtProof quickly detects and identifies missing text, graphics,

incorrect fonts and text sizes, as well as broken type and color deviations.

is the first 64-bit artwork inspection solution

for Mac and Windows environments.

Are you 100% confident that no critical errors have been missed?

ArtProof can help you

- PDF compare for artwork inspection

- Compare artwork to PDF files

- Proofread PDF documents, artwork, and .AI files

- Pre-press proofing, pre-press quality control

- Packaging quality control

Inspect

- Artwork

- Revision

- Proofs

- Imposition files

- Nested artwork

- Cartons

- Leaflets

- Booklets

ArtProof Benefits

- Native Mac OS and Windows support

- Inspect artwork files

- Reduce approval cycles by catching errors early

- Shorten time to market

- Avoid costly errors for file revisions and proofs

- Check supplier proofs to ensure accuracy

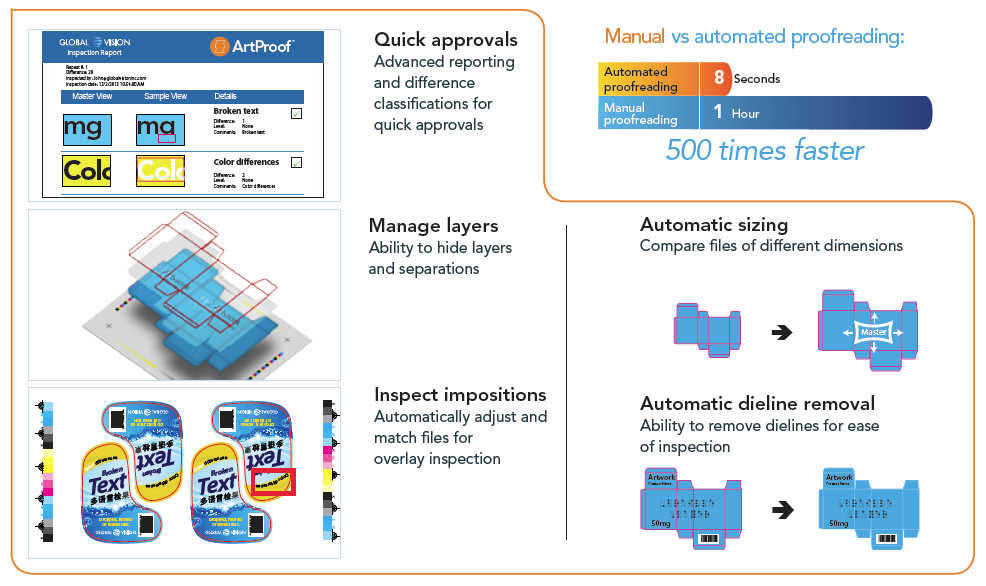

ArtProof Advanced Technologies

- Supports 1-bit TIFF files

- New 64-bit architecture

- Layers and separation management

- Ability to hide layers/separations by default

- Inspects imposition files (step and repeat files)

- Automatic adjust and match files for overlay inspection

- Inspects colors, graphics and copy

- Supports live and outlined text Auto-locates repeats

- Automation for booklet inspection (multi-page)

- Automatic sizing

- Detect with pixel precision all

differences regardless of sample size

- Automatic dieline management

- Ability to remove dielines for ease of inspection

- Dynamic and comprehensive reporting

- Easy reporting and commenting for

fast and accurate results

- Difference classification

ArtProof Inspection Reports

ArtProof Supported File Types

Inspect Word to PDF, Compare Text to PDF documents

with complete accuracy in seconds

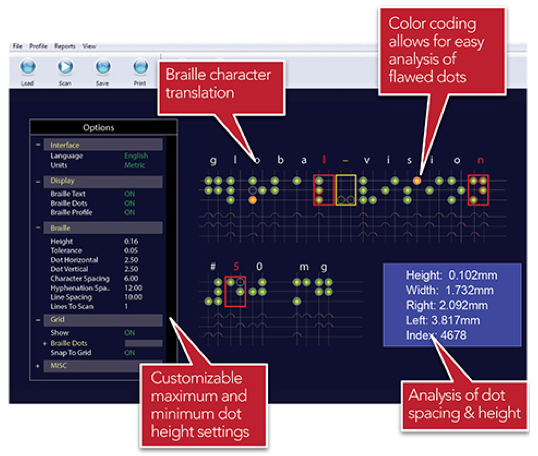

BrailleProof - Braille Inspection & Verification Tool

BrailleProof is a Braille inspection and Braille verification tool

that digitally inspects Braille text for added or missing Braille components,

to ensure that the Braille matches the approved PDF.

BrailleProof also converts Braille components into

readable text, ensuring accuracy of the Braille.

BrailleProof is designed to meet all Braille standards

for pharmaceutical Braille packaging,

including the Marburg Medium font standard.

With BrailleProof, you can be rest assured that all Braille is accurate,

readable and meets international standards,

while eliminating manual checking, and reducing inspection times.

Integrates with ArtProof artwork inspection software.

How accurate is your Braille Packaging?

Typical Use Case:

Proofreading of pharmaceutical carton in seconds

Inspect with great accuracy

- Pharmaceutical Braille packaging

- Healthcare Braille packaging

- Pharmaceutical cartons

- Embossed Braille cartons

- Braille labels

- Consumer product goods Braille packaging

- Braille inserts

BrailleProof Features

- Detects missing or added Braille dots

- Translates Braille during inspection into readable text

- Measures Braille dot spacing

- Braille character recognition

- Extensive reporting, detailing pass/fail for each Braille dot

- Color coding allows for easy analysis of flawed dots

- FDA 21 CFR Part 11 / EMA Annex 11 compliant

- Validation available

BrailleProof Benefits

- Ensures your PDF matches the printed Braille component

- Meets all Braille standards for pharmaceutical and

healthcare Braille packaging,

including the Marburg Medium font standard

- Ensures Braille content, layout and placement on packaging is correct

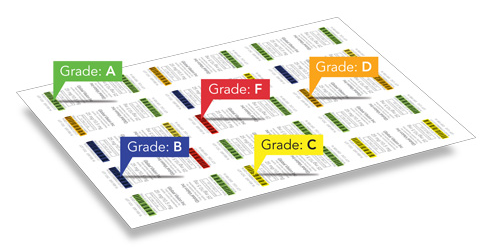

BarProof - Barcode Decoder & Verifier

BarProof is a barcode verification tool that builds quality into

your process by taking it all the way upstream to your PDF files.

Barcode verification is your insurance policy for

the highest quality barcode in your supply chain,

thus enhancing your supplier customer relationship.

Verify all barcodes on an entire press sheet in one pass!

BarProof automatically locates and verifies all barcodes on a label,

carton or press sheet and grades each according to

CEN/ANSI/ISO standards.

Bar width reduction (BWR) and magnification measurements are

also provided ensuring scannable barcodes at the checkout counter.

BarProof verifies and decodes 1D and 2D barcodes,

including UPC, Data Matrix and QR.

The BarProof barcode verification module is available as an option

with ArtProof, and ScanProof.

BarProof Benefits

- Instantly locate & grade all barcodes on a press sheet

- Simple to use

- Grade Barcodes in PDF Files - Unique in the Market!

- Bar width reduction measurement

- Barcode magnification measurement

- Decode & grade 1D & 2D barcodes

including Data Matrix, QR, MicroQR

- Grade each barcode according to CEN/ANSI/ISO standards

- Verifies and decodes linear 1D and 2D barcodes

- Color coded pass / fail reporting for barcodes

- 21 CFR Part 11 / EMA Annex 11 compliant

- Integrates with ScanProof print inspection solution

- No need for more hardware,

use existing ScanProof scanner

Standards Compliance

- ISO/IEC 15416

- ISO/IEC 15415

21 CFR Part 11 / Annex 11

Decoding Only

Bar Width Reduction (BWR)

BWR is critical during the pre-press process in order

to compensate for different packaging materials and

ink spread during production.

By verifying BWR values in PDF files upstream in the process,

brand owners can be assured that barcodes will achieve

expected quality levels.

Barcode Grading Criteria

- Decode

- Checks the difference between

the minimum and maximum reflectance of the scan line.

- Symbol Contrast

- Checks that the minimum reflectance is less

than half of the maximum reflectance.

- Minimum Reflectance

- Checks the smallest edge contrast found in the scan line.

- Minimum Edge Contrast

- Checks the ratio of

the minimum edge contrast to the symbol contrast.

- Modulation

Checks the ratio of

the minimum edge contrast to the symbol contrast.

- Defects

- Checks for reflectance non-uniformity along the scan line.

- Decodability

Supported Symbologies

Decoding and Grading:

- Codabar

- Code 39

- Code 128

- Interleaved 2 of 5

- Pharma Code

- RSS-14

- RSS-14 Stacked

- RSS-Expanded

- RSS-Expanded Stacked

- RSS-Limited

- EAN/UPC (13 Digits)

- EAN/UPC (8 Digits)

- UPC-A

- UPC-E

Scan360 Cylinder Scanner

Scan360 is the leading artwork inspection scanner for cylinders.

Eliminate errors found on cylindrical packaging components.

Designed for the consumer packaged goods (CPG) and pharmaceutical markets,

Scan360 will directly scan the surface of any cylindrical item and

automatically compare it to the approved proof.

Scan and inspect with great accuracy

- Large heavy gauge metal cans

- Ribbed cans

- Embossed text

- Rough textured plastic finishes

- Shrink wrapped cylindrical items

- Aluminum cans

- Glass jars

- Plastic bottles

- Soft metallic containers

- Polymer tubes

Scan360 Features

- Detects missing, added or broken elements

- Detects print defects

- Scans in under 20 seconds

- Inspects cylindrical diameters from1”(25.4mm) – 6.8”(172.72mm)

- Resolution: 300 dpi

Scan360 Benefits

- Ensures the print quality on your cylindrical packaging

- Automates your inspections

- Anti-counterfeit inspection

BraillePoint - Braille Dot Height Measurement Tool

BraillePoint is a Braille dot measurement tool perfect for measuring

Braille dot height and verifying Braille dot placement.

With BraillePoint, users can ensure the precision of all embossed

and screen printed Braille found on cartons and labels.

BraillePoint uses advanced electronic measurement technologies

to measure Braille dot height directly.

Unlike scanner and camera based measurement systems that are

dependent on dot shadows and complex algorithms, BraillePoint is

capable of providing the most accurate results.

With BraillePoint, you can be rest assured that all Braille is accurate,

readable and meets international standards, while eliminating

manual checking, and reducing inspection times.

Braille presence module the ability to compare Braille dots from a

BraillePoint scan to a Braille presence template.

The master Braille presence template may be created in two ways:

- Extraction of Braille dots from a PDF

- Manually

Inspection reports include both comparison and translation.

BraillePoint integrates with ScanProof print inspection solution.

BraillePoint Benefits

- Accurately measure Braille dot height

- Reduce Braille dot inspection times

- Ensure accuracy & quality of Braille text

- Ensure compliance with international standards (Marburg Medium)

BraillePoint Features

- Braille presence module

- Time zones stamps on all inspection reports

- Analysis of dot spacing & height

- Braille character recognition

- Extensive reporting, detailing pass/fail for each Braille dot

- Color coding allows for easy analysis of flawed dots

- Customizable maximum and minimum dot height settings

- Superior sample scan times

- Inspection setup details easily saved

- 21 CFR Part 11 / EMA Annex 11 compliant & validation available

Braille Measurement Tool Report

System Requirements:

Computer Software:

- Windows 7 (64-bit)

- User Access Level: Administrator, User

- PDF Support: PDF Viewer for reporting

Braille Dot Height Measurement Unit/Hardware:

- Windows 7 (64-bit)

- 2.0GHz Dual Core CPU (64-bit CPU)

- RAM: 6GB minimum

- HDD: 160MB free space

- Monitor Size: 24" widescreen

- Resolution: 1280x1024 recommended (1024x768 minimum)

- CD-ROM-Drive: Any standard drive

|