Part of NewFormat AB Portal

OpenFormat

Products and Services

Offerings / Promotions / Prices

Guides and Datasheets

Customer Contact Form

Home/NewFormat

NewFormat AB

PDF standards make the world work

Our solutions are based on

tested, reliable, and highly accessible software solutions.

NewFormat is Appointed Reseller and Solution Partner in

Nordic (Sweden, Denmark, Finland, Iceland, Norway)

and

Baltic Region (Estonia, Latvia, Lithuania)

of InSoft Imp, from InSoft Automation, USA.

InSoft Imp

Solutions for Layout Planning and Impositioning for

Digital & Offset Printing

|

Products

|

Click Here for Free Trial of InSoft Imp

(You will be asked to fill in a trial request form.

To help us identify your interest for the software

and support you, please enter the code "NewFormat"

in the "Preferred Reseller" form field).

|

Imp Overview

Imp

a fully automatic layout planning and imposition software

Imp is a fully automatic layout planning and imposition

software designed to simplify and automate the process of

creating cost effective, print ready layouts for

commercial and packaging printers.

Imp includes several key innovations and has

sophisticated algorithms to offer a one-click solution

for creating imposed layouts.

Imp handles any kind of job

(book work, ganging & packaging jobs)

on sheet fed as well as web fed presses.

Imp is capable of calculating the best print/die layouts for jobs of

any size, quantity & color thus making it an ideal tool for estimators.

In a few seconds, your estimators can graphically

evaluate the best way to lay-out a job,

while minimizing printing and finishing costs.

The estimators can evaluate the trade-offs between

material efficiency, printing costs & finishing costs

to the last penny!

Imp for Book Printing

Imp for Gang Printing

Imp for Labels and Packaging

Die Library

StylKit CAD

Benefits

Automation

Efficiency

- Saves material & time through efficient planning

Ease of use

- With all the intelligence built in, efficient, accurate and

consistent imposition layouts can be produced.

Reduce human errors

- Imp constantly evaluates the layouts against

the constraints defined by printing, folding,

die cutting and other finishing process and

keeps the user informed of any problems.

Single interface

- Single tool for estimators,

planners & prepress operators.

- Single tool for your packaging, label,

ganging & bookwork layout creation needs.

- Drive both printing and die cutting

from the same application.

Key Features

Bound Jobs

- Feed in the parameters like final trim size,

number of pages, copies, binding style and in

one click create cost effective and RIP-ready layouts.

- Plan and impose landscape books, Arabic books,

table top calendars and N-up binding books with

no additional effort.

- Generate plan and imposition for complex web fed scenarios

involving multiple webs and multiple delivery systems,

with the same ease.

Packaging and other non-rectangular jobs

- Starting from a single-up die line, create cost-effective

RIP ready layouts in one click.

- Using a highly sophisticated interlocking and nesting

algorithm, find the most cost effective way of printing

the job across different sheet sizes and presses.

- Completely automated, behind the scenes bleed resolution.

- Dynamically search die-database based on

geometry to find re-usable dies.

Auto Ganging

- Starting from a CSV file, gang multiple jobs across all

possible sheet sizes in one click.

- Using a nesting algorithm,

refined over the last 15 years and

now adapted for printing needs,

minimize press time and paper wastage.

- Rearrange elements on layouts to achieve

cutting simplicity and logical order.

- Gang non-rectangular jobs which

require die-cutting, with equal ease.

New Features

Support for Large Format Presses

- Ground-up support for large format presses.

Imp is a rapid print layout creation engine

for large format presses.

Both roll-to-roll and flat-bed format presses are supported.

In the configuration of those devices,

one can use specific cost parameters,

allowing Imp to calculate accurate job costs.

- Ganging Algorithm Fine-tuned for Large Format Printing.

When planning on a large format press,

the ganging algorithm of Imp works differently.

With less emphasis on reducing number of layouts and

more on saving substrate and ink, Imp will find the most

cost effective ganged layouts.

Imp is also capable of considering and

placing the same job on multiple layouts.

- New Digital Cutting Machine Category.

Again with the goal of making cost effective layouts

for large format scenarios, Imp introduces a new

machine category: Digital Cutting Machines.

The cost function of this machine can calculate

the cost of digitally cutting a layout

(with knife or laser).

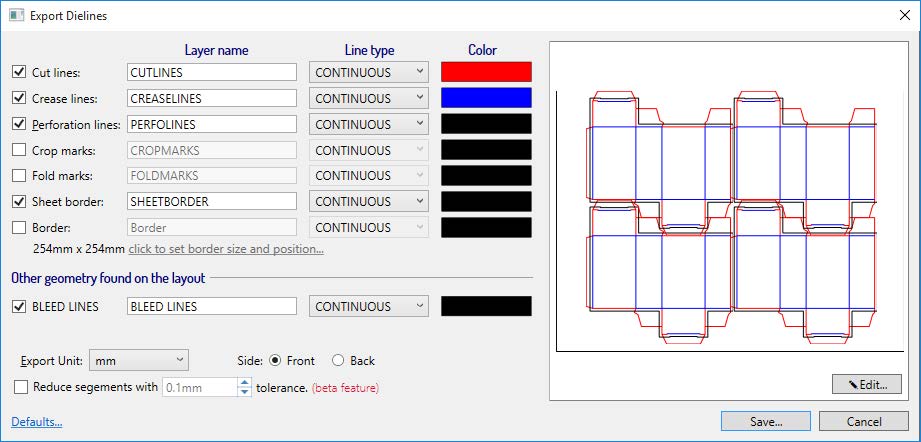

Improvements to Die Export

Considerable focus on handling of CAD data.

CAD-like Editor to Make Corrections

to Geometry of a JobUntil now, geometry of an unbound component could

be set only by importing CAD files (DXF, CF2 or PDF).

No changes could be done to the CAD data within Imp.

This has changed; you can now make changes from

within Imp by choosing the 'Edit Geometry' option.

Currently this CAD Editor has only some basic functionality.

But, going forward you can expect considerable development

adding more and more features to this CAD Editor.

This editor can come in handy in the following situations:

- Make corrections to a badly drawn outline so

that Imp can find the closed outer geometry.

- Add holes or other special layers from within Imp.

- You can even draw the entire outline directly in Imp.

However, please note that it is a non-parametric editor.

Edit Die Export Data before ExportingThe same CAD Editor mentioned above comes in handy

when you want to add some new lines or layers to

the die data, just before exporting it.

The editor also has a smart tool called

'Auto Repeat Selection', which can automatically repeat

any geometry you add over one or more stations.

This tool is very handy when you want to

add stripping rules to the die.

Note: You cannot delete existing geometry of the layout.

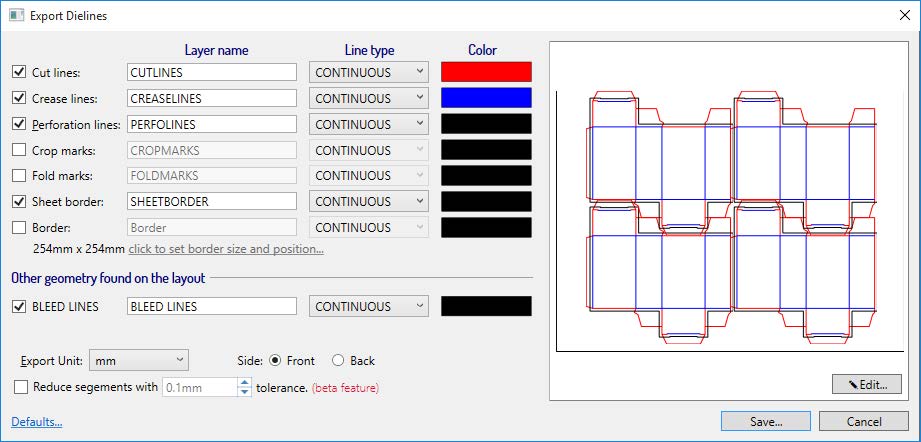

Preview of Die when ExportingThe Die Export window now shows dynamic preview of

the die to the right (as shown in the picture below).

Preview is shown as per the layers settings

you have configured on the left.

More Control on Other GeometryFor other geometry layers,

you can now control two more things other than its color:

- The line style (dash/dot etc.)

- Whether the geometry in this layer will require

some rules to be made when making the die.

Imp will remember these settings and automatically

apply them in the future for layers with matching names.

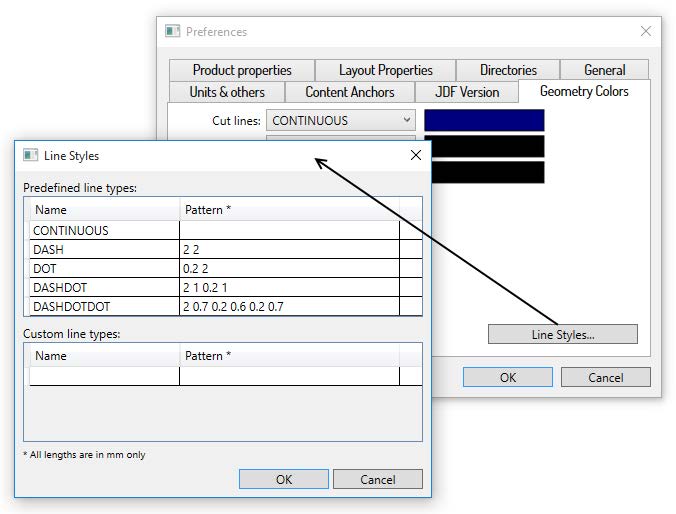

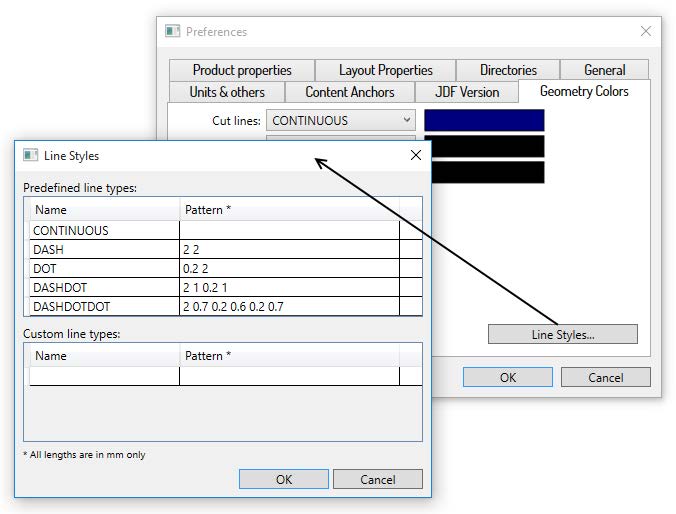

More Control on Line StylesYou can now control how different line styles

are rendered inside Imp's user interface.

These settings also affect the line style

exported to DXF or PDF die.

You can also add new line types.

Below you can see the popup-window that allows you

to define and control the different line styles.

You must enter a series of values in millimeters.

These values alternately define the stroke and space length.

While you can delete custom line types,

predefined line types cannot be deleted.

Option to Draw All Layers in Layout ReportBefore version 8, Imp would only draw

the cut-outline of the jobs in reports.

By choosing the new option 'Show all die lines',

you can now make Imp draw a to-the-scale

die drawing in the same place.

When this option is checked,

Imp will also draw a line legend in the report for

the reader to identify which lines belong to which layer.

Other New Features

- It is now possible to define a soft and hard limit to

the die rule length that your die equipment can handle.

When auto planning, Imp software will take this limit

into consideration and generate layout solutions

which do not exceed the hard limit.

It will raise a warning when the soft limit is crossed.

- Improved Push & Pop planning efficiency.

- It is now possible to select multiple .lyt files when

planning with layout template file(s) option.

- Imp can now expand gutters of signatures at

the time of auto planning bound component.

It is no longer necessary to manually click

the Expand gutters menu to expand the gutters.

Gutter = the space between columns of printed text,

including the gap between facing pages.

- Number of lines/points in

the exported CAD data can be reduced.

By approximating series of small line segments with arcs.

In some cases, this can drastically reduce the file size of

the exported die/CAD data.

- Additional columns in the CSV files will now be

imported as custom properties of the component.

Such a CSV file must have header row

at the beginning of the file.

- Better error reports are generated when a CSV file or

few lines of a CSV file fail to import.

- It is now possible to include and print

manually filled data in layout reports.

- It is now possible to define custom properties

for layouts just the same way as it is possible to

define for a product or component.

- New option to save Imp reports as .xps file

while generating them through ImpFlow.

- Plan information can be exported in a CSV format.

- By setting an option in impui.ini file,

it is now possible to align jobs on

the outside in a ganged layout.

This can simplify guillotine cutting.

- PDF and job-size mismatch warning

is now shown in the Product Sheet UI.

- Maximum folding depth value

can now be imported through the material CSV file.

- You can now precisely control

the quiet zone around a barcode mark.

- Creep compensation can now be applied

by scaling of the content.

- Imp now supports Offcut margins for unbound components.

You can use this margin to enforce additional space

around the job on the layout.

- Like bleed margin, offcut margin is also measured from

the trim edge of the job and hence will have effect only

when its value is greater than the bleed margin value

on a given edge.

|

For more information contact NewFormat

NewFormat AB

Smörblommegränd 14, SE-165 72 Hässelby (Stockholm), Sweden

tel:+46 (0)70 631 53 01

All content © copyright 2008-2024 NewFormat AB. All rights reserved.

All product names, trademarks and registered trademarks

are property of their respective owners.

InSoft Automation Partner

|

|